Mechanism Of Action Of Crusher Aids In The Cement Production Ma石灰石i

Study on structureperformance relationship and action mechanism

2024年6月1日 This paper focuses on the structureperformance relationship and action mechanism of nine organic chemicals in cement GAs Based on the results presented, the following conclusions can be drawn: The GAs performance of alkanolamines depends on 2023年11月6日 Grinding aids (GAs) are polar chemicals introduced in cement mills in either liquid or powder form to improve on mill grindability efficiency Studies have shown Review of the Effect of Grinding Aids and Admixtures on the 2020年9月20日 The major grinding aid mechanism is to reduce adhesive and cohesive particle forces • The additiveinduced change of the particle and bulk behavior Grinding aids for dry fine grinding processes – Part I: Mechanism 2021年12月6日 Grinding aids, first introduced into cement manufacturing in 1930 , are surfaceactive substances that facilitate particle comminution during the milling process In the production of Portland cement, grinding The Effect of Various Grinding Aids on the

.jpg)

Effects of grinding aids on model parameters of a cement

2019年2月15日 This research focuses on investigating the effects of the three different grinding aids, consisting of a mixture of amine, glycol and polyol in different ratios, on the 2023年11月6日 Studies have shown that some GAs not only help in grinding efficiency but also play vital roles in improving the product particle size distribution, product ability to flow in the mill, grinding(PDF) Review of the Effect of Grinding Aids and 2003年12月1日 This is a broad overview of the use of cement additives in the cement production, focusing on the mechanism of action of grinding aids (GA) A distinction will Action of grinding aids in cement production Request PDF2024年3月24日 采用性原理方法研究了它们在硅酸三钙(CS)表面的吸附和分散构型的工作机制。 作为GA的结构参数,极性基团的数量被发现影响水泥熟料的粉磨效率。 Study on structureperformance relationship and action

.jpg)

Improvement of cement performances through the use

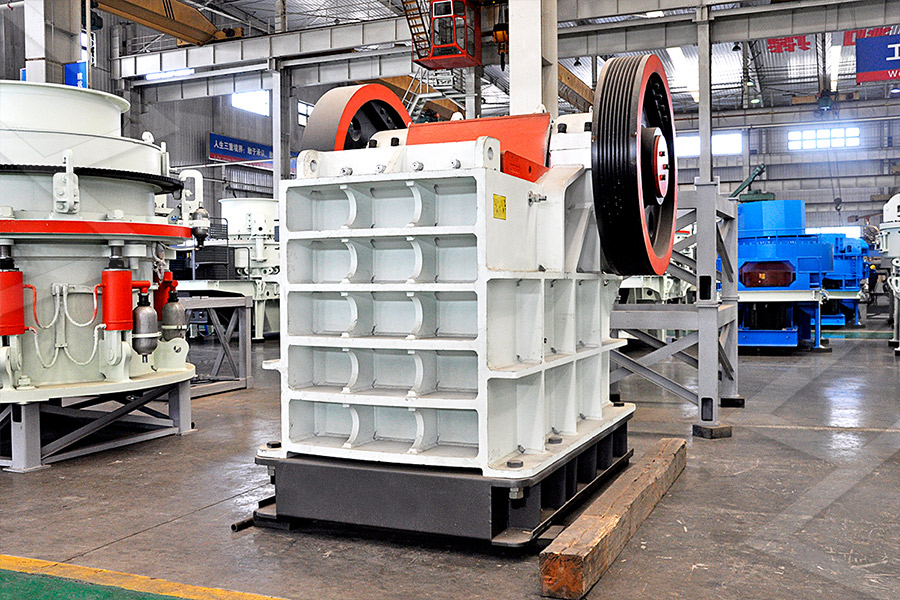

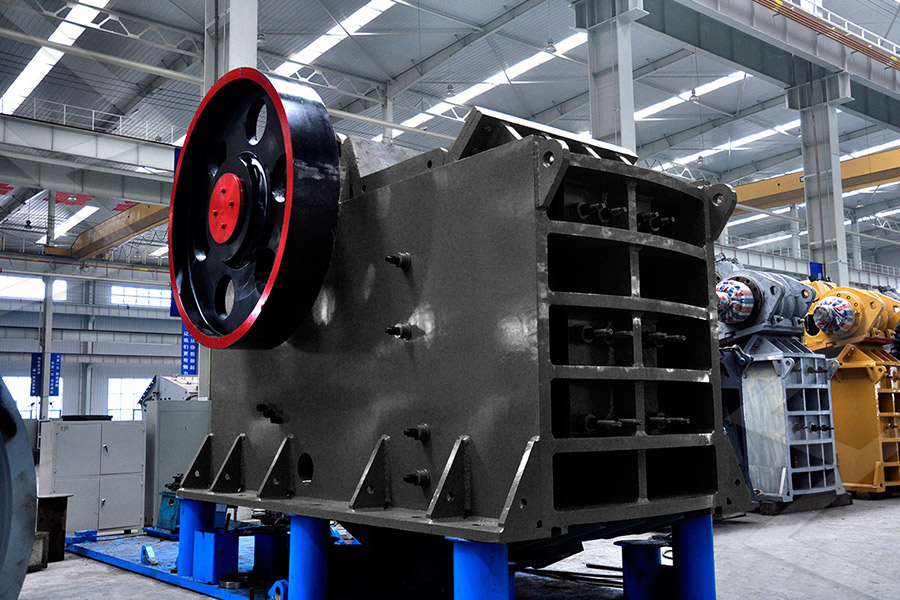

2023年7月25日 In addition, the use of a suitable grinding aid can improve the particle size distribution of cement and positively influence clinker hydration, thus improving the 2005年6月16日 Abstract and Figures In cement industry, clinker grinding in steel tumbling mills has a very low energy efficiency The use of a small quantity of products called grinding aids can improve the(PDF) A study on the action mechanisms of 2024年1月18日 Figure 1 : Cement production process block diagram 2 Cement production step by step 21 Limestone rock crushing Limestone rock crushing typically involves the use of a crusher machine The type of machine used for this purpose can vary depending on the specific application and the desired final product sizeCement Production Demystified: StepbyStep Process and Jaw crushers are used for the crushing of very hard and abrasive raw materials for cement manufacturing Jaw crushers are a type of earlier crushing equipment, which is still widely used in smelting, building Cement Crusher Crushers for Cement Plant

Grinding aids for dry fine grinding processes – Part I: Mechanism

2020年9月20日 1 Introduction The history of grinding aids in dry fine grinding processes starts in the late 1930s with the application of the first commercial grinding aids in the cement industry [1]Since that time, the importance of grinding aids in industrial dry fine grinding processes has strongly increased; so did the number of scientific papers dealing Mechanism Of Action Of Crusher Aids In The Cement Production Mapei [PDF] INVESTIGATION ABOUT THE EFFECT OF CHEMICAL 2018年3月29日 Their mechanism of action is still unclear, but it is believed to involve the formation of a monomolecular organic layer on cement surface or the neutralization of electrostatic forces formed during Mechanism Of Action Of Crusher Aids In The Cement Production 2021年12月6日 Grinding aids, first introduced into cement manufacturing in 1930 [], are surfaceactive substances that facilitate particle comminution during the milling processIn the production of Portland cement, grinding aids are added in small amounts in the range of 001 to 010% by weight of cement, according to the PNEN 1971 standard []They allow The Effect of Various Grinding Aids on the Properties of Cement Host and manage packages Securityen/124/cement crusher aidsmd at main dinglei2022/en

.jpg)

Cement Manufacturing Process INFINITY FOR CEMENT EQUIPMENT

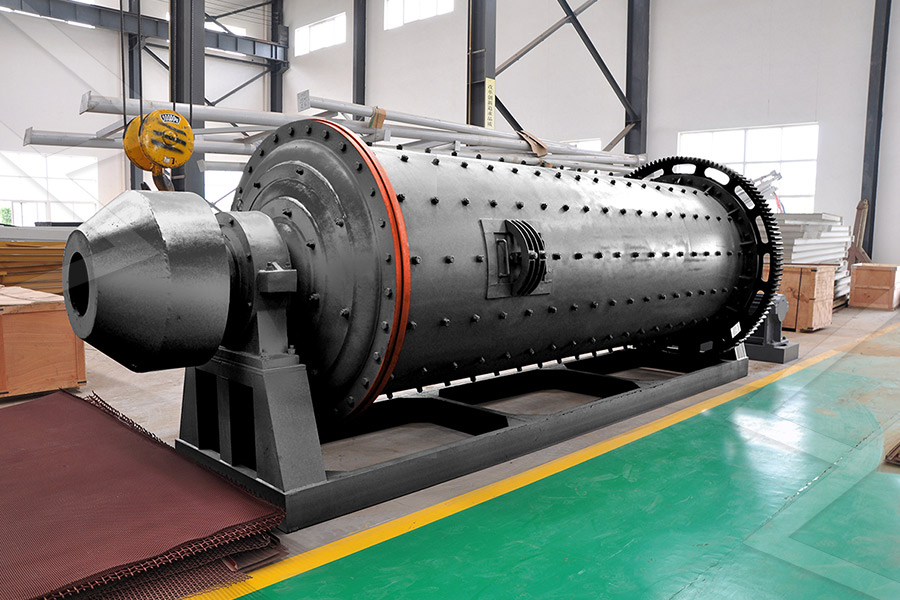

Clinker production is the most energyintensive stage in cement production, accounting for over 90% of total industry energy use Clinker is produced by pyroprocessing in kilns These kiln systems evaporate the free water in the meal in preheater cyclone, calcite the carbonate constituents (calcination) in calciner, and form Portland cement 2014年6月1日 The composition of coalgangue and the phase change procedure of calcinations activation were analyzed in this paper by Fourier transformation infrared spectrometer (FTIR) and infrared microscopeEffect of Grinding Aids on the Particles Characteristics of Cement 1992年9月1日 In an attempt to delineate the mechanism of action of grinding aids in comminution the effect of these additives on the subprocesses of grinding, vis breakage and attrition, has been studied by isolating each one of them through specially designed experiments in a laboratory ball millAlso, the flow characteristics of limestone powder Mechanism of action of grinding aids in comminution2022年1月14日 1 Introduction Grinding aids, first introduced into cement manufacturing in 1930 [], are surfaceactive substances that facilitate particle comminution during the milling processIn the production of Portland cement, grinding aids are added in small amounts in the range of 001 to 010% by weight of cement, according to the PNEN 1971 standard []The Effect of Various Grinding Aids on the Properties of Cement

.jpg)

(PDF) Review of the Effect of Grinding Aids and

2023年11月6日 The review finally recommended that the future course of action in the production of blended cements should apply GAs This is in order to help produce highly replaced blended cements that are 2020年9月20日 Grinding aid additives are established in various industrial dry fine grinding processes, primarily to achieve either a) an increase of the production capacity, b) a decrease of the specific energy consumption or c) finer particles or a better product performance However, even though numerous related scientific papers have already Grinding aids for dry fine grinding processes – Part I: Mechanism 2023年9月10日 Divisione Additivi di Macinazione 2 ®® RESULTS AND DISCUSSION We set up a grinding procedure uti lizing a lab mill, Bond type, in orde r to check the ef fectiveness ofGRINDING AIDS: A STUDY ON THEIR MECHANISM OF Semantic Scholar extracted view of "Grinding aids increase the productivity and costeffectiveness of cement production A comprehensive experimental test program and a variety of computer simulations were used to determine the physical and chemical mechanisms of action" by M Weibel et alGrinding aids increase the productivity and cost

A practical guide to improving cement manufacturing

2024年5月22日 The cement production process 1 The Quarry: The cement production process begins with the extraction of limestone and clay from the quarry 2 Crusher and PreBlending: The material is then crushed to reduce particle sizes and blended to reduce variability in composition 3 Raw Mill and Kiln: Raw materials and additives are2024年9月8日 The limestone is crushed in the first crusher called a jaw crusher and then fed into the second crusher called an impact crusher with mixing of clays to reduce particle size below 50mm The discharged raw mix (limestone 70percnt;, clays 30percnt;) is fed onto a belt conveyor and passed across a bulk material analyzerManufacturing process Lafarge2018年8月1日 The use of grinding aids can significantly improve clinker production and fineness while decreasing energy consumption, which can help reduce the costs and CO2 emissions associated with cement (PDF) Effect of Grinding Aids in Cement GrindingThe discharge system of the silo for cement would be designed for controlled cement dispensation It has a coneshaped base and an outlet valve that enables proper regulation to ensure release at manageable flow rates to the downstream process This system is vital in supplying cement on a constant basis to concrete batching plants and other usersUnderstanding the Working Mechanism of a Cement Silo

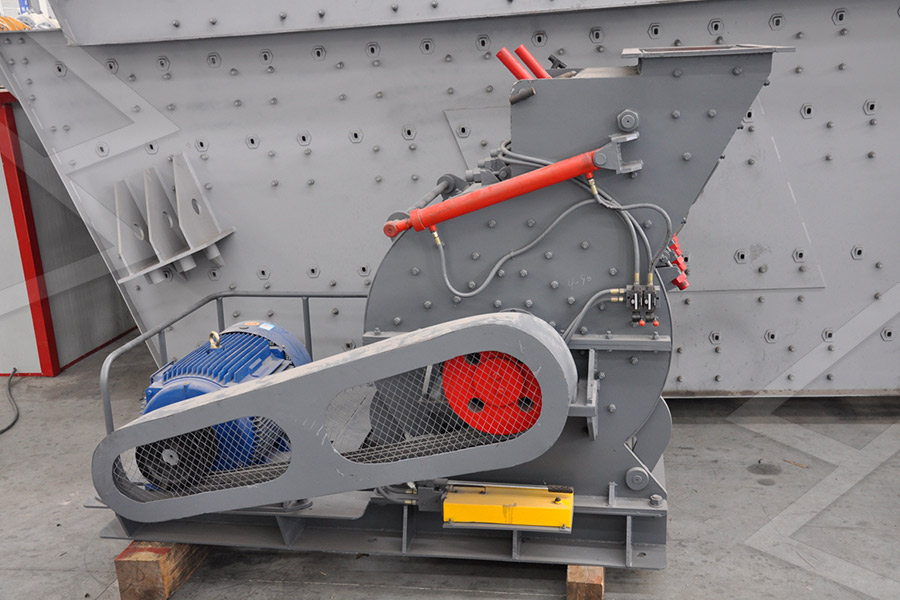

The Complete Guide to Primary Crushing, Secondary

2023年2月28日 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide Discover the types of crushers used in each stage, their working principles, and the advantages and disadvantages of each process Get answers to frequently asked questions and improve your understanding of Effects of triethanolamine grinding aids on the angle of repose, fineness, particle morphology and particle size distribution of cement are studied, and the action mechanism of grinding aids is discussed by surface tension and Zeta potential The results show that the powder fluidity and particle circularity of cement are improved and the particle size and grinding Effect of Grinding Aids on the Particles Characteristics of Cement and 2023年10月23日 The use of grinding aids can significantly improve clinker production and fineness while decreasing energy consumption, which can help reduce the costs and CO2 emissions associated with cement A study of different grinding aids for lowenergy cement clinker production2023年11月15日 A study of different grinding aids for lowenergy cement clinker production by SRM Zan1 and KEHK Ishak1 Synopsis Cement production requires significant energy, and entails high costs and CO2 emissions This is because the clinker requires very fine grinding Grinding aids can improve production and finenessA study of diferent grinding aids for lowenergy cement

Mechanism of action of grinding aids in comminution

1992年9月1日 Semantic Scholar extracted view of "Mechanism of action of grinding aids in comminution" by S K Moothedath et al Over recent years, polycarboxylate superplasticizers have found their way into grinding aids used in cement production to reduce the electrical energy consumption The effectiveness of these large Expand 152023年4月1日 The paper offers a theoretical substantiation of the mechanism of action of additives during cement grinding caused by the removal of surface electrostatic chargesOn the mechanism of action of cement grinding aids2022年4月15日 In this study, it is aimed to give a new viewpoint of choosing utilization rates and type of grinding aids (GA), taking into account cementpolycathoxylate etherbased waterreducing admixture (PCE) compatibility For this purpose, the effects of amine and glycolbased GA utilization rate on clinker grinding efficiency and the physical Effect of amine and glycolbased grinding aids utilization Cement Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary Some deposits are mined by underground methods Softer rocks such as chalk and clay can be Cement Extraction, Processing, Manufacturing Britannica

.jpg)

Nearterm pathways for decarbonizing global concrete production

2023年7月29日 New cement production could be curtailed through improved utilization and life extension of instock resources for concrete systems; this curtailment in turn would influence the amount of GHG 2014年10月15日 Study on structureperformance relationship and action mechanism of organic chemicals in cement grinding aids Show abstract Grinding aids (GAs) are an important addtive in the cement production process However, the relationship between the molecular structure of GAs and its grinding efficiency has not been clearly revealed In The influences and selection of grinding chemicals in cement grinding This is a summary of the use of cement additives in the cement production, focusing on the mechanism of action of grinding aids (GA) what is grinding aid Home Crusher Solution 02 mapei clinker grinding aid Print mapei clinker grinding aidHenan Mining Machinery and Equipment Manufacturer2023年10月13日 The cement industry plays a crucial role in the global economy as it is used in the production of various infrastructure and construction projectsGlobal database of cement production assets and upstream

A study of diferent grinding aids for lowenergy cement

2023年10月16日 A study of different grinding aids for lowenergy cement clinker production by SRM Zan1 and KEHK Ishak1 Synopsis Cement production requires significant energy, and entails high costs and CO2 emissions This is because the clinker requires very fine grinding Grinding aids can improve production and fineness2011年7月1日 Cement will remain the key material to satisfy global housing and modern infrastructure needs As a consequence, the cement industry worldwide is facing growing challenges in conserving material and energy resources, as well as reducing its CO 2 emissions According to the International Energy Agency, the main levers for cement Sustainable cement production—present and futureWhile calcined clays, mainly metakaolin, have been used as SCMs and in the production of cement in many places around the world [8, 11,12,13,14,15,16], advances in admixture technologies have enabled a renewed interest in calcined clays, as some of the challenges identified when using calcined clays (eg reduced workability, high water demand Clay calcination technology: stateoftheart review by the 2023年12月11日 Achieving lowcarbon development of the cement industry in the developing countries is fundamental to global emissions abatement, considering the local construction industry’s rapid growthProjecting future carbon emissions from cement production

.jpg)

The Cement Plant Operations Handbook International

2019年4月30日 cement production –10 Regional cement consumption data –11 EU Environmental legislation –12 Ship and truck capacities –13 Patents B10 Conversion tables 317 1 Length – 2 Volume – 3 Pressure – 4 Weight – 5 Area – 6 Density – 7 Energy – 8 Force – 9 Miscellaneous References 318 Index 335 Advertisers’ index 2024年6月1日 Grinding aids (GAs) are a kind of additive commonly used in cement, which can effectively reduce the energy consumption of cement research and production processes [1], [2] It has been confirmed that the addition of GAs of 001 %–005 % by cement weight to ball mills can significantly increase the machinehour output of cement Study on structureperformance relationship and action mechanism 2020年7月1日 Grinding aids to increase grinding efficiency in cement production are materials that can produce large amounts of highquality cement in a short time by reducing surface energy by preventing Grinding aids for dry fine grinding processes – Part I: Mechanism 2023年1月2日 Compared with the cement paste without ultrasonic action, the change pattern of shear stress of cement paste after ultrasonic action is similar to it Fitting the variation law of shear stress in cement paste after ultrasonic action by Bingham's model The relationship equation is shown in (2) (2) τ = 2290 + 019 γ ̇Strengthening mechanism of ultrasonic action on

Everything about Cement Production Thermo Fisher Scientific

2024年3月1日 So, we’ve put together a list of our blog articles related to the cement production process and analysis Here are the top 15 of our most read cement articles, in no particular order: Extending Quarry Life through Raw Material Analysis in Cement Production While the life of a cement plant quarry is by its very nature finite, it can be 2024年1月18日 Figure 1 : Cement production process block diagram 2 Cement production step by step 21 Limestone rock crushing Limestone rock crushing typically involves the use of a crusher machine The type of machine used for this purpose can vary depending on the specific application and the desired final product sizeCement Production Demystified: StepbyStep Process and Jaw crushers are used for the crushing of very hard and abrasive raw materials for cement manufacturing Jaw crushers are a type of earlier crushing equipment, which is still widely used in smelting, building Cement Crusher Crushers for Cement Plant2020年9月20日 1 Introduction The history of grinding aids in dry fine grinding processes starts in the late 1930s with the application of the first commercial grinding aids in the cement industry [1]Since that time, the importance of grinding aids in industrial dry fine grinding processes has strongly increased; so did the number of scientific papers dealing Grinding aids for dry fine grinding processes – Part I: Mechanism

Mechanism Of Action Of Crusher Aids In The Cement Production

Mechanism Of Action Of Crusher Aids In The Cement Production Mapei [PDF] INVESTIGATION ABOUT THE EFFECT OF CHEMICAL 2018年3月29日 Their mechanism of action is still unclear, but it is believed to involve the formation of a monomolecular organic layer on cement surface or the neutralization of electrostatic forces formed during 2021年12月6日 Grinding aids, first introduced into cement manufacturing in 1930 [], are surfaceactive substances that facilitate particle comminution during the milling processIn the production of Portland cement, grinding aids are added in small amounts in the range of 001 to 010% by weight of cement, according to the PNEN 1971 standard []They allow The Effect of Various Grinding Aids on the Properties of Cement Host and manage packages Securityen/124/cement crusher aidsmd at main dinglei2022/enClinker production is the most energyintensive stage in cement production, accounting for over 90% of total industry energy use Clinker is produced by pyroprocessing in kilns These kiln systems evaporate the free water in the meal in preheater cyclone, calcite the carbonate constituents (calcination) in calciner, and form Portland cement Cement Manufacturing Process INFINITY FOR CEMENT EQUIPMENT

.jpg)

Effect of Grinding Aids on the Particles Characteristics of Cement

2014年6月1日 The composition of coalgangue and the phase change procedure of calcinations activation were analyzed in this paper by Fourier transformation infrared spectrometer (FTIR) and infrared microscope1992年9月1日 In an attempt to delineate the mechanism of action of grinding aids in comminution the effect of these additives on the subprocesses of grinding, vis breakage and attrition, has been studied by isolating each one of them through specially designed experiments in a laboratory ball millAlso, the flow characteristics of limestone powder Mechanism of action of grinding aids in comminution2022年1月14日 1 Introduction Grinding aids, first introduced into cement manufacturing in 1930 [], are surfaceactive substances that facilitate particle comminution during the milling processIn the production of Portland cement, grinding aids are added in small amounts in the range of 001 to 010% by weight of cement, according to the PNEN 1971 standard []The Effect of Various Grinding Aids on the Properties of Cement