Flowsheet Cop石灰石r Processing Dwg

.jpg)

PROCESS COMPRESSION AND FLOWSHEET DEVELOPMENT FOR

2021年12月8日 Development of a flowsheet starts with identification of raw material(s) and potential product(s) and byproduct(s) First step in the development of flowsheet is Model performance assessed with linear correlation coefficient (r), root mean square error (RMSE), mean absolute percentage error (MAPE) and scatter index (SI) indicated that pulp chemistry A typical flowsheet for processing refractory gold ore The flowsheet specifies the nominal design, peak production flow rate, and equipment sizing to handle those capacities Manufacturers provide ratings for their equipment, Crushing Plant Design and Layout Considerations 911 MetallurgistThe Mikheevskii MPE, producing 18 million t of porphyry copper ore per year (at a grade of 04% copper), applies the bulkdifferential flowsheet and produces copper and Current Status of CopperOre Processing: A Review

.jpg)

Flowsheet considerations for copper cobalt projects SciELO

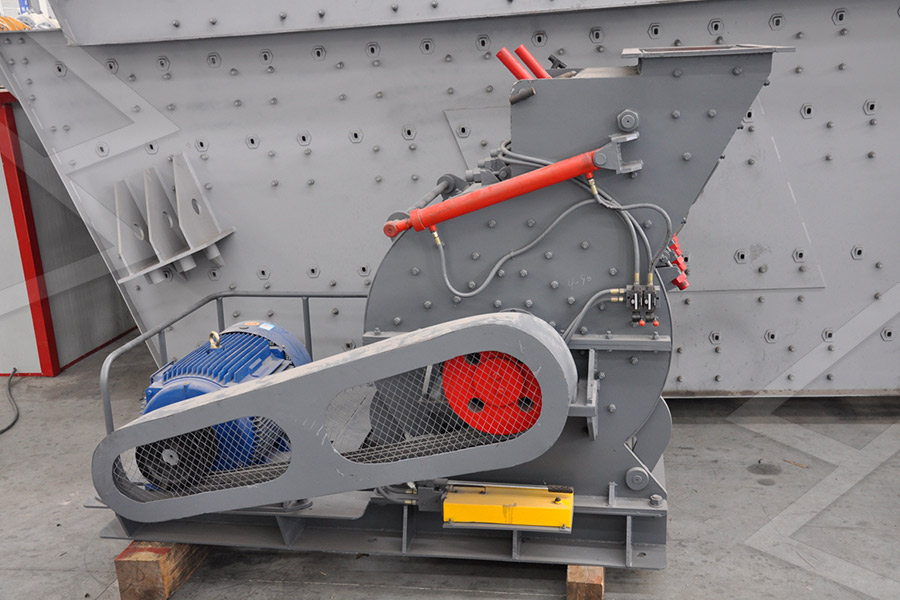

A bleed steam of copper SX raffinate is neutralized to remove acid, and copper and cobalt are recovered by sequential precipitation This flowsheet is the simplest configuration for An integrated flowsheet consisting of sorting, crushing/grinding, physical separation, acid leaching, solvent extraction, and selective precipitation was designed to achieve Enhancement of a Process Flowsheet for Recovering and 2005年1月1日 Block flowsheets provide an overview of a complex process or plant, with a drawing made with rectangular blocks to represent individual processes or groups Flowsheets ScienceDirectContext 1 processing system applied in mineral industry is the set of machines performing operations of crushing, classifying, separating, conveying or storing Fig1 An example of flowsheet of the real aggregate processing system

.jpg)

Process Design and Flowsheet Development Mineral Technologies

process flowsheet designs for new and existing mineral processing circuits We are a certified quarantine station and our Australian test facility has the capacity to work with 图纸介绍 : 石灰石破碎车间图纸 行业用途 : 机械设备 建筑家具 设计软件 : AutoCADZWCAD 版本/编辑 : 文件格式 : dwg 下载权限 : 普通会员等级及以上石灰石破碎车间CAD图纸图纸下载机械数模资料 开拔网Typical Iron Ore Beneficiation Flow Sheet Multotec specialises in iron ore beneficiation equipment with over 50 years of global experience and leading technology Our team of metallurgists and engineers will partner with you Iron Ore Processing Flowsheet Multotec2015年8月26日 This flowchart made of machinery icons explains or expresses in simple but clear terms the step of the Copper Mining and Copper Extraction Process Starting from either openpit or underground Copper Mining Extraction Process Flow Chart

.jpg)

181 Process Flow Diagram (PFD) Symbols for Engineers

181 Process Flow Diagram (PFD) Symbols for Engineers Welcome to our process flow diagram symbols list Scroll down and use the table of contents on the left to navigate this page and see the different symbol types most commonly used by engineersBut first, let’s review the purpose and benefits ofTypical Tin Beneficiation Flow Sheet Multotec specialises in tin beneficiation equipment with over 50 years of global experience and leading technology Our team of metallurgists and engineers will partner with you to customise your equipment, helping your process run more efficiently while lowering your overall cost per tonTypical Tin Processing Flowsheet Multotec2018年1月1日 However, at feature sizes below 1 μm, the delay from the interconnects becomes significant, and can dominate the total delay unless the process and design are optimizedAt the 14nm node and below, the delay from interconnects is comparable to that of the devices [8]The total delay in a circuit has contributions from both the device delay Process Technology for Copper Interconnects ScienceDirect2016年3月10日 In the majority of cases, the last crushing stage is closed circuited using anywhere from 10MM (3/8″) square to 14MM (9/16″) slotted openings on the sizing deck In some copper concentrators, the mill feed is all passing 13MM(½”), using three stages of crushing and 14MM (9/16″) square openings on the closed circuit screensCrushing Plant Flowsheet DesignLayout 911 Metallurgist

A New Age Gold Plant Flowsheet Gekko S

The flowsheet for the treatment of highgrade gold ores involves utilising proven processing paths The flowsheet may be divided into four basic steps (Refer to Fig 1) 1 Crushing and grinding 2 Gravity concentration 3 Intensive cyanidation 4 Tailings disposal CRUSHING AND GRINDING ROM GRAVITY CONCENTRATION O/S U/S TAIL2016年3月8日 The Mineral Processing Flowsheets shown on the following pages are based on actual data obtained from successful operating plants Metallurgical data are shown in these flowsheets which incorporate Crushers, Grinding Mills, Flotation Machines, Unit Flotation Cells, and Selective Mineral Jigs as well as other standard milling Mineral Processing Flowsheets 911 MetallurgistDownload scientific diagram Simplified flow sheet of black copper smelter process (secondary copper smelting) [59] Reprinted with permission from [59], 2013 from publication: Metal Extraction Simplified flow sheet of black copper smelter process (secondary copper copper processing plant layout Feldspar Crusher Sales XSM copper processing plant crushing plant flowsheet symbol dwg Quarry grinding plant Designed to bring the same ease of use to flowsheet drawing mineral processing flowsheet GOLD PLANT PROCESS FLOW Related Information european make jaw crusher; flow chart rock Gold Processing Plant Layout Dwg

.jpg)

flowsheet copper processing dwg

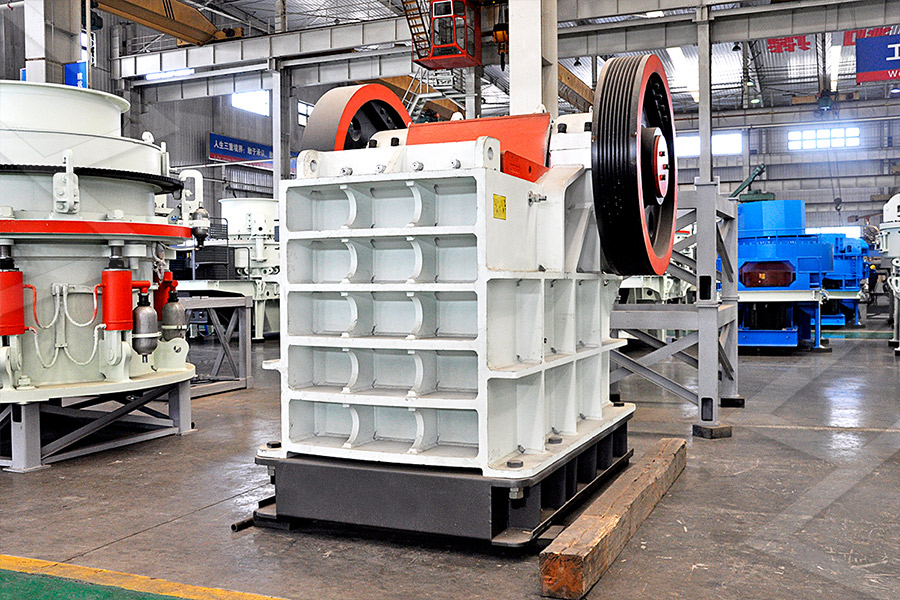

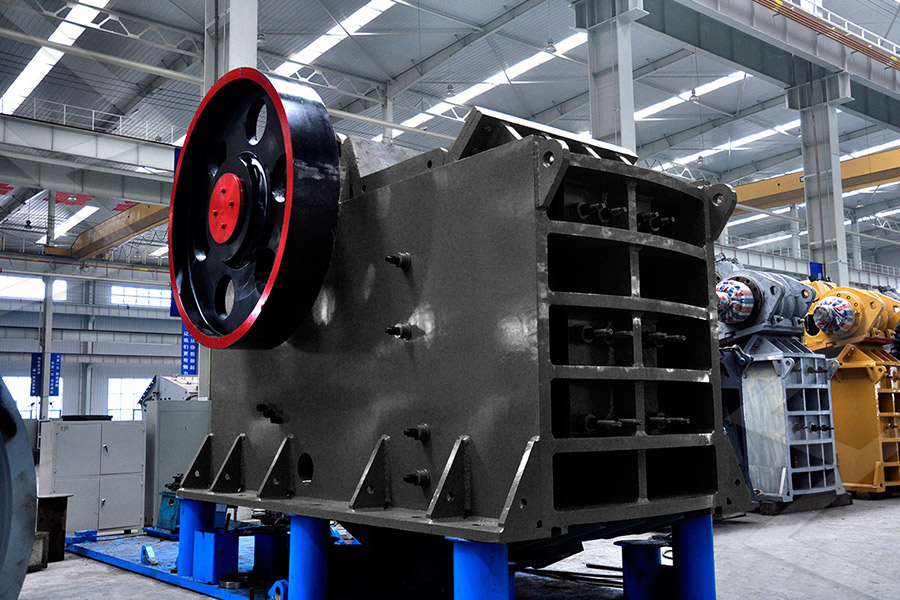

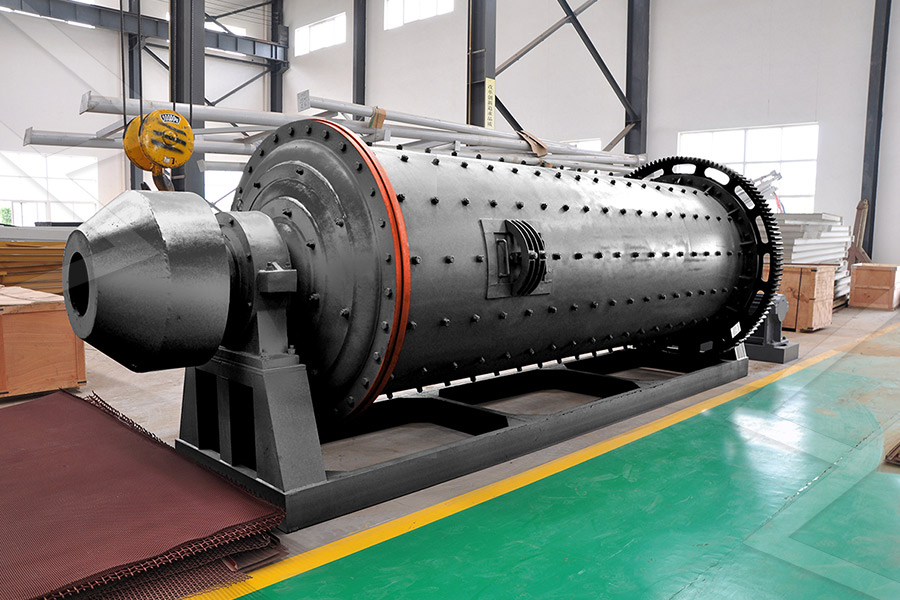

ball mill flowsheet dwg and crushing plants flowsheet copper processing dwg 24 Sep 2012 Posts Related to ball mill flowsheet dwg cad drawing for jaw crusher bucket WhatsApp mining process of zinc ore The flowsheet above was designed to treat economically approximately 200 tons in 24 Typical Gold CIP and CIL Beneficiation Flow Sheet Multotec specialises in gold beneficiation equipment with over 50 years of global experience and leading technology Our team of metallurgists and engineers will partner Typical Gold CIP and CIL Beneficiation Flow SheetTypical PGM (Platinum Group Metals) Beneficiation Flow Sheet Multotec specialises in PGM (Platinum Group Metals) beneficiation equipment with over 50 years of global experience and leading technologyTypical PGM (Platinum Group Metals) Beneficiation Flow Sheet Ontario Operations Flowsheet 2007 •Coleman •Copper Cliff North Copper Anode Matte Processing Grinding Magnetic Separation Fluid Bed Roasting Metallics Nickel Sulfide Nickel Oxide Copper Sulfide Flotation • Nickel Oxide to Clydach Storage Crushing VBN concentrates ~ 19% • Copper AnodesOntario Operations Flowsheet

The six main steps of iron ore processing Multotec

The best advice that we at Multotec can give you is to use products specially adapted to iron processing and also get to know your machines Our team of experts can help you with any questions you may have about cyclones, spirals, drums and samplers, and provide support during the stages of iron ore processing Iron Ore Flow SheetTypical Copper (Sulphide) Beneficiation Flow Sheet Multotec specialises in copper (sulphide) beneficiation equipment with over 50 years of global experience and leading technology Our team of metallurgists and engineers will partner with you to customise your equipment, helping your process run more efficiently while lowering your overall cost per Typical Copper (Sulphide) Beneficiation Flow Sheet Multotec2016年3月10日 by L D Michaud February 29, 2024 March 10, 2016 Categories Flotation, Flowsheets Flowcharts Tags Copper Flotation, Copper Froth Flotation, Small Process Equipment Previous NextFlowsheet of Copper Extraction Process by Froth Flotation2018年5月21日 Hydromet Processing of Copper, Nickel Cobalt Sulphides Forum 2123 May 201 8 Perth, Australia These resins were succ essfully piloted for the Kak anda flowsheet (now Bos s Mining) for the Flowsheet options for cobalt recovery in African coppercobalt

Processing Plant Flowsheet Design SRK Consulting

Processing Plant Flowsheet Design The foundation for superior process design is sound ore deposit knowledge and comprehensive testwork Our metallurgists are experienced in designing and supervising comprehensive test programs for 2017年4月11日 Figure 153 is the flow sheet of the Miami concentrate retreatment and filter plants The ores are composed of chalcocite and pyrite with subordinate amounts of oxidized copper minerals disseminated Copper Ore Processing Methods 911 MetallurgistDescarga este bloque CAD en DWG Flowsheet planta industrial de quimicos Saltar al contenido ACCEDER Blog; Explorar; Revit Families; CAD Viewer New; BIM Viewer; Join the Libreria CAD Community! Subscribe to our newsletter and get exclusive access to free DWG and BIM files, plus the latest trends in architecture and constructionFlowsheet Planta Industrial En DWG (28946 KB) Librería CAD2018年10月25日 African Copperbelt operations have traditionally focused on copper production; however, it has now become imperative to also consider cobalt recovery from these ores A plethora of processing routes is possible Most hydrometallurgical flowsheets recover cobalt from the raffinate of the lowgrade copper solventextraction circuitFlowsheet Options for Cobalt Recovery in African Copper–cobalt

.jpg)

Flowsheet options for processing copper gold and gold copper

Copper and gold have similar cyanide metallurgy depending on the nature of the minerals present The processing of gold copper and copper gold ores can be highly problematic, site specific and the process selection is dependent on ore grade, mineralogy, acid leach behaviour, cyanide chemistry, product saleability and environmental considerations The Download scientific diagram Flow sheet of processes for the recovery of copper and copper alloys from scrap Low grade scrap is usually smelted in shaft furnaces but also in other furnaces, eg Flow sheet of processes for the recovery of copper and copper The oxidative leach can be operated under a range of pH conditions, varying from acidic to neutral For the processing of a refractory gold/silver concentrate, the pH of the oxidative leach is held at 55 by the continual addition of limestone slurry to ensure complete oxidation of the sulphur to sulphateFlowsheet Options Glencore TechnologyThe European Journal of Mineral Processing and Environmental Protection Vol 2, No 2, 13030868, 2002, pp 94102 Technical Note Development of a Flowsheet for Recovering Copper and Tin from Copper Refining Slags F Arslan 1*, K Giray2, G Önal1, V Gürkan 1 Istanbul Technical University, Mining Faculty, Mining Engineering DepartmentDevelopment of a Flowsheet for Recovering Copper and Tin from Copper

.jpg)

Process Design Principles SpringerLink

2021年11月30日 A common general flow sheet for copper oxide/secondary sulfide leaching and metal recovery is shown on the righthandside of Fig Overview of general Sepon processing flow sheet elements Based on data in Typical Mineral Sands Beneficiation Flow Sheet Multotec specialises in mineral sands beneficiation equipment with over 50 years of global experience and leading technology Our team of metallurgists and engineers will partner with you to customise your equipment, helping your process run more efficiently while lowering your overall cost per tonMineral Sands Processing Flowsheet MultotecTypical Manganese Beneficiation Flow Sheet Multotec specialises in manganese beneficiation equipment with over 50 years of global experience and leading technology Our team of metallurgists and engineers will partner with you to customise your equipment, helping your process run more efficiently while lowering your overall cost per tonTypical Manganese Beneficiation Flow Sheet Multotec2024年8月21日 “We are delighted to have secured this significant contract which represents further industry acceptance of Weir’s differentiated sustainable and costeffective redefined flowsheet solution, with our market leading HPGR technology particularly suited for the waterscarce climate and geology of the Reko Diq coppergold project,” he saidWeir awarded $102m (£53m) redefined flowsheet contract for

shibang/sbm flowsheet copper processing dwgmd at master

You cannot select more than 25 topics Topics must start with a letter or number, can include dashes ('') and can be up to 35 characters longAs deposits with free, coarse gold were depleted and the volume of mining increased, process flowsheet design became more and more complicated We use cookies to give you a Another factor that contributes to the complexity of processing gold ores is the presence of adsorptionactive substances that trap dissolved gold and carry it Gold Project Flowsheet Design SRK ConsultingDownload scientific diagram A typical flowsheet for processing refractory gold ore (Sulphidic Gold Ore) Numbers represent unit operations and sample points in red from publication A typical flowsheet for processing refractory gold ore (Sulphidic combined refinery flowsheet It is benefitted from feedforward and feedbackward information of the product streams as well as from the state and performances of the unit processes [78], such as offgas train and its gas handling capacity, or solution purification of the tank house and its limits in,Taskinen, Pekka; Jokilaakso, Ari; Lindberg, Daniel; Xia, Jiliang

.jpg)

Process flowsheet development for recovering antimony from

2013年8月1日 Flowsheet diagram for antimony recovery from copper concentrate It is important to state that copper concentrates containing arsenic minerals as enargite (Cu 3 AsS 4 ), tennantite (Cu 12 As 4 S 13 ) and others apart from arsenopyrite (FeAsS) which is inert to the leaching solution can be treated in this process with a significant removal of 2018年10月25日 Request PDF Flowsheet Options for Cobalt Recovery in African Copper–cobalt Hydrometallurgy Circuits The price of cobalt has increased by some 450% in the past two years, mainly due to Flowsheet Options for Cobalt Recovery in African Copper–cobalt IN PROCESSING COPPER ORES In recent times, a low copper content in ores has been observed (ores containing 02–03% copper are used for processing in Canada and the United States, and ores containing at least 04% copper are used in Russia [4]) owing to the exhaustion of rich copper resources The flowsheet of processing copper ores isCurrent Status of CopperOre Processing: A ReviewFLOWSHEET DEVELOPMENT FOR GOLD OREBODIES OVERVIEW There are several basic metallurgical flowsheets used to treat gold orebodies, with a great many permutations recovery by standard processing techniques, and can be due to either chemical or physical interference An example of chemical interference is theFLOWSHEET DEVELOPMENT FOR GOLD OREBODIES SGS

.jpg)

Typical Coal Beneficiation Flow Sheet

Typical Coal Beneficiation Flow Sheet Multotec specialises in coal beneficiation equipment with over 50 years of global experience and leading technology Our team of metallurgists and engineers will partner with you to customise your equipment, helping your process run more efficiently while lowering your overall cost per tonTypical Iron Ore Beneficiation Flow Sheet Multotec specialises in iron ore beneficiation equipment with over 50 years of global experience and leading technology Our team of metallurgists and engineers will partner with you Iron Ore Processing Flowsheet Multotec2015年8月26日 This flowchart made of machinery icons explains or expresses in simple but clear terms the step of the Copper Mining and Copper Extraction Process Starting from either openpit or underground Copper Mining Extraction Process Flow Chart181 Process Flow Diagram (PFD) Symbols for Engineers Welcome to our process flow diagram symbols list Scroll down and use the table of contents on the left to navigate this page and see the different symbol types most commonly used by engineersBut first, let’s review the purpose and benefits of181 Process Flow Diagram (PFD) Symbols for Engineers

Typical Tin Processing Flowsheet Multotec

Typical Tin Beneficiation Flow Sheet Multotec specialises in tin beneficiation equipment with over 50 years of global experience and leading technology Our team of metallurgists and engineers will partner with you to customise your equipment, helping your process run more efficiently while lowering your overall cost per ton2018年1月1日 However, at feature sizes below 1 μm, the delay from the interconnects becomes significant, and can dominate the total delay unless the process and design are optimizedAt the 14nm node and below, the delay from interconnects is comparable to that of the devices [8]The total delay in a circuit has contributions from both the device delay Process Technology for Copper Interconnects ScienceDirect2016年3月10日 In the majority of cases, the last crushing stage is closed circuited using anywhere from 10MM (3/8″) square to 14MM (9/16″) slotted openings on the sizing deck In some copper concentrators, the mill feed is all passing 13MM(½”), using three stages of crushing and 14MM (9/16″) square openings on the closed circuit screensCrushing Plant Flowsheet DesignLayout 911 MetallurgistThe flowsheet for the treatment of highgrade gold ores involves utilising proven processing paths The flowsheet may be divided into four basic steps (Refer to Fig 1) 1 Crushing and grinding 2 Gravity concentration 3 Intensive cyanidation 4 Tailings disposal CRUSHING AND GRINDING ROM GRAVITY CONCENTRATION O/S U/S TAILA New Age Gold Plant Flowsheet Gekko S

Mineral Processing Flowsheets 911 Metallurgist

2016年3月8日 The Mineral Processing Flowsheets shown on the following pages are based on actual data obtained from successful operating plants Metallurgical data are shown in these flowsheets which incorporate Crushers, Grinding Mills, Flotation Machines, Unit Flotation Cells, and Selective Mineral Jigs as well as other standard milling Download scientific diagram Simplified flow sheet of black copper smelter process (secondary copper smelting) [59] Reprinted with permission from [59], 2013 from publication: Metal Extraction Simplified flow sheet of black copper smelter process (secondary copper